Pengeringan Gas Alam yang Hemat Biaya untuk Peningkatan Produksi Papan Silikat Kalsium

Detail produk:

| Tempat asal: | CINA |

| Nama merek: | OSMANUV |

| Sertifikasi: | ISO9001 |

| Nomor model: | OSM-LRHG-1320T |

Syarat-syarat pembayaran & pengiriman:

| Kuantitas min Order: | 1 set |

|---|---|

| Harga: | Bisa dinegosiasikan |

| Kemasan rincian: | Kemasan kayu |

| Waktu pengiriman: | 35 hari |

| Syarat-syarat pembayaran: | T/t |

| Menyediakan kemampuan: | Perundingan |

|

Informasi Detail |

|||

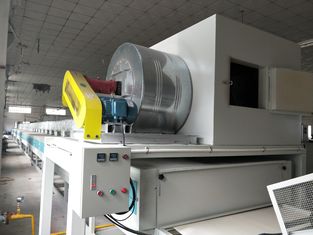

| Nama Produk: | Mesin pengering gas alam sepanjang 28 meter | dimensi (l*w*h): | Ukuran Khusus, 28000mm * 2400mm * 3140mm |

|---|---|---|---|

| Kekuatan: | 24kw | Voltase: | 380V/50Hz |

| Lebar lapisan: | 1320mm | Kecepatan pelapis: | dapat disesuaikan, 0,5-8m/mnt |

| Jaminan: | 1 tahun | Kondisi: | Baru |

| Menyoroti: | Mesin pengeringan gas alam,pengering papan silikat kalsium industri,peralatan pengeringan gas yang hemat biaya |

||

Deskripsi Produk

Pengeringan Gas Alam yang Hemat Biaya untuk Peningkatan Produksi Papan Silikat Kalsium

Deskripsi Produk

Lini pengeringan gas alam ini dirancang khusus untuk papan silikat kalsium, menyediakan distribusi panas yang seragam dan kontrol suhu yang presisi selama proses pengeringan. Sistem ini memastikan penghilangan kelembaban yang optimal sambil menjaga integritas papan dan stabilitas dimensi.

Parameter Teknis

| Parameter | Spesifikasi |

|---|---|

| Model |

OSM-LRHG-1320T |

| Sumber Pemanas | Sistem Pembakar Gas Alam |

| Suhu Maksimum | 300°C |

| Lebar Konveyor | 1320 mm (Dapat Disesuaikan) |

| Zona Pengeringan | 6 zona (Dapat Disesuaikan) |

| Konsumsi Bahan Bakar | 15-25 m³/jam |

| Sistem Kontrol | PLC + Layar Sentuh HMI |

Aplikasi

Pengeringan dan pengawetan papan silikat kalsium, panel tahan api, dan bahan langit-langit arsitektur.

Kustomisasi

-

Dapat Disesuaikan konfigurasi zona pengeringan

-

Dapat Disesuaikan kecepatan dan lebar konveyor

-

Dapat Disesuaikan profil suhu

Fitur

-

Distribusi panas yang seragam

-

Kontrol suhu yang presisi

-

Operasi yang hemat energi

-

Konstruksi yang kokoh

Dukungan dan Layanan

-

Pengawasan instalasi

-

Program pelatihan operator

-

Garansi 12 bulan

-

Dukungan teknis

Pengepakan dan Pengiriman

-

Krat kayu tugas berat

-

Pengemasan tahan cuaca

-

Standar ekspor profesional

FAQ

T: Berapa tingkat konsumsi energi?

J: Konsumsi rata-rata adalah 18-22 m³/jam tergantung pada persyaratan produksi.