Robot Gantry Tugas Berat untuk Penanganan Panel & Pulp Molding.

Detail produk:

| Tempat asal: | Cina |

| Nama merek: | OSMANUV |

| Sertifikasi: | ISO9001 |

| Nomor model: | OSM-GR-1320 |

Syarat-syarat pembayaran & pengiriman:

| Kuantitas min Order: | 1 Set |

|---|---|

| Harga: | Bisa dinegosiasikan |

| Kemasan rincian: | Kotak Kayu |

| Waktu pengiriman: | 30 ~ 45 hari |

| Syarat-syarat pembayaran: | T/T |

| Menyediakan kemampuan: | perundingan |

|

Informasi Detail |

|||

| Jaminan: | Garansi Produsen 1 Tahun | Asal: | Cina |

|---|---|---|---|

| Warna: | biru, putih, hijau untuk pilihan | Ukuran konveyor: | menyesuaikan |

| Fungsi: | Mengangkut | Kecepatan Kerja: | 1-10m/mnt |

| Disesuaikan: | Ya | Penggunaan: | Sebagai permintaan Anda |

| Menyoroti: | Robot Gantry Tugas Berat untuk Otomasi,Robot Penanganan Panel Pakai Beban Tinggi,Robot Gantry Pemuatan Pulp Molding |

||

Deskripsi Produk

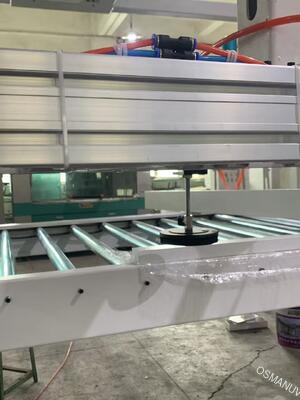

Robot Gantry Tugas Berat untuk Penanganan Panel & Cetakan Pulp | Otomatisasi Pemuatan/Pembongkaran Beban Tinggi

Deskripsi Produk:

Robot gantry tugas berat ini dirancang untuk pemuatan dan pembongkaran bahan lembaran (seperti panel, kaca, dan bahan komposit) dan produk tiga dimensi (seperti produk cetakan pulp) yang sepenuhnya otomatis, presisi, dan andal. Dibangun di atas rangka modular yang kaku, ia menawarkan kustomisasi yang tinggi area kerja dan opsi end-effector untuk berintegrasi secara mulus ke dalam lini produksi, menggantikan tenaga kerja manual dan meningkatkan efisiensi, konsistensi, dan keselamatan.

Komposisi Integrasi Lini Produksi:

-

Rangka Gantry Modular Kaku (sumbu X, Y, Z)

-

Sistem Penggerak Servo Presisi Tinggi & Panduan Linier

-

Dapat Disesuaikan End-Effector (Penjepit Mekanik, Susunan Cangkir Hisap Vakum, Perlengkapan Khusus)

-

Pengontrol Logika yang Dapat Diprogram (PLC) & Sistem Kontrol Gerak

-

Pagar Keselamatan & Tirai Cahaya (Opsional)

-

Antarmuka Integrasi dengan Peralatan Hulu/Hilir (Konveyor, Tekan, Pengering)

-

Panel Kontrol Operator (HMI)

Parameter Teknis:

| Kategori Parameter | Detail & Spesifikasi |

|---|---|

| Struktur Gantry | Profil aluminium atau baja modular, ukuran dapat disesuaikan |

| Jumlah Sumbu | Standar 3-sumbu (X, Y, Z), dengan sumbu putar (A) opsional |

| Rentang Perjalanan (X, Y, Z) | Sepenuhnya dapat disesuaikan (misalnya, X: 2000-6000mm, Y: 1000-3000mm, Z: 500-1500mm) |

| Akurasi Penentuan Posisi | ±0.1mm (khas) |

| Kecepatan Maksimum | Hingga 2 m/s (linier, tergantung pada beban dan perjalanan) |

| Muatan Maksimum | Dapat Disesuaikan dari 10 kg hingga 300 kg+ |

| Sistem Kontrol | PLC industri dengan pengontrol gerak khusus, HMI yang mudah digunakan |

| Pemrograman | Teach pendant dan/atau pemrograman PC offline |

| Persyaratan Daya | 380V / 50Hz / 3-Fase (standar, dapat disesuaikan) |

| Komunikasi | Ethernet/IP Standar, Profinet, dll., untuk integrasi lini |

Aplikasi:

-

板材行业: Industri Panel: Pemasukan/pengeluaran otomatis untuk router CNC, gergaji panel, lini pengecatan, dan penumpukan/penghilangan tumpukan kayu lapis, MDF, papan partikel, lembaran logam.

-

纸浆模塑行业: Industri Cetakan Pulp: Pengambilan dan penempatan kecepatan tinggi produk cetakan pulp basah/kering (如 baki, peralatan makan) dari mesin cetak ke konveyor atau rak pengeringan, penumpukan, dan paletisasi.

Kustomisasi:

Nilai inti dari sistem kami terletak pada kustomisasi yang luas. Kami menyesuaikan rentang perjalanan, kekakuan struktur, kapasitas muatan, kecepatan gerakan, dan yang paling penting, perkakas end-effector (area vakum, jenis penjepit, perlengkapan khusus) untuk menangani ukuran, berat, bentuk (lembaran datar atau cetakan pulp 3D yang kompleks), dan permukaan material produk spesifik Anda.

Fitur:

-

Kekakuan & Presisi Tinggi: Memastikan penentuan posisi yang stabil dan akurat untuk tugas penanganan berulang.

-

Perkakas Fleksibel: End-effector yang dapat diubah dengan cepat memungkinkan satu sistem untuk menangani berbagai jenis produk.

-

Keandalan Tinggi: Dirancang untuk pengoperasian 24/7 di lingkungan industri dengan perawatan minimal.

-

Integrasi Mulus: Komunikasi mudah dengan mesin hulu dan hilir untuk otomatisasi terkoordinasi.

-

Peningkatan Keselamatan: Menghilangkan pekerja dari peran penanganan manual yang berulang, berat, atau berbahaya.

Dukungan dan Layanan:

Kami menyediakan dukungan proyek lengkap, termasuk desain tata letak, pengawasan instalasi, pelatihan pemrograman & pengoperasian yang komprehensif, garansi satu tahun, dukungan diagnostik jarak jauh, dan suku cadang yang tersedia.

Pengepakan dan Pengiriman:

Komponen struktural utama dikemas dengan aman dalam peti kayu. Panduan presisi dan komponen listrik dikemas secara terpisah dan dilindungi dari kelembaban dan guncangan. Ketentuan pengiriman (FOB, CIF, dll.) dapat dinegosiasikan berdasarkan tujuan.

FAQ:

-

T: Bisakah ia menangani produk rapuh seperti barang cetakan pulp basah?

-

J: Tentu saja. Melalui dapat disesuaikan perkakas cangkir vakum (menggunakan cangkir lunak dan gaya hisap yang dapat disesuaikan) dan profil gerakan yang lembut, ia dapat menangani barang-barang halus tanpa kerusakan.

-

-

T: Bagaimana cara memprogramnya? Apakah sulit bagi operator kami untuk belajar?

-

J: Itu diprogram melalui teach pendant intuitif dengan antarmuka grafis. Kami menyediakan pelatihan langsung untuk memastikan operator Anda dapat dengan percaya diri menjalankan dan melakukan penyesuaian program dasar.

-

-

T: Bisakah satu robot gantry melayani beberapa mesin?

-

J: Ya, area kerja yang dapat disesuaikan yang luas dapat dirancang untuk mencakup titik pemasukan dan pengeluaran dari beberapa stasiun (如 beberapa mesin press atau CNC), memaksimalkan ROI.

-

-

T: Berapa waktu tunggu untuk sistem ukuran khusus?

-

J: Waktu tunggu bervariasi berdasarkan kompleksitas kustomisasi. Desain modular standar memiliki waktu tunggu yang lebih singkat. Garis waktu terperinci disediakan setelah finalisasi spesifikasi teknis.

-

-

T: Apakah Anda menyediakan rekayasa integrasi dengan lini produksi kami yang ada?

-

J: Ya, kami menawarkan solusi turnkey. Insinyur kami akan bekerja sama dengan Anda untuk merancang antarmuka (mekanik dan listrik) untuk integrasi yang mulus dengan konveyor, mesin press, atau sistem kontrol spesifik Anda.

-