High-Efficiency Infrared Drying Line for Furniture Board & Molded Pulp Products - Energy-Saving Thermal Solution

Detail produk:

| Tempat asal: | CINA |

| Nama merek: | Osmanuv |

| Sertifikasi: | ISO9001 |

| Nomor model: | OSM-UV-1320T |

| Dokumen: | 5 Meters IR Drying Machine.pdf |

Syarat-syarat pembayaran & pengiriman:

| Kuantitas min Order: | 1 set |

|---|---|

| Harga: | Bisa dinegosiasikan |

| Kemasan rincian: | Kotak kayu |

| Waktu pengiriman: | 45 hari |

| Syarat-syarat pembayaran: | T/t |

| Menyediakan kemampuan: | Perundingan |

|

Informasi Detail |

|||

| Kecepatan sabuk conveyor: | 10-30m/mnt | Sumber cahaya: | Cahaya uv |

|---|---|---|---|

| meja kerja: | Mengapung | Merek Inverter: | Schneider |

| Pistol semprot: | mengadopsi pistol semprot otomatis GRACO Amerika | Daya Tahan Lapisan: | Daya Daya Tinggi |

| Cara Lapisan: | DOD Kepala Inkjet | Jenis rol: | Kawat baja |

| Menyoroti: | infrared drying machine for furniture board,energy-saving infrared drying line,thermal drying solution for molded pulp |

||

Deskripsi Produk

High-Efficiency Infrared Drying Line for Furniture Board & Molded Pulp Products - Energy-Saving Thermal Solution

Keywords: infrared drying line, furniture board drying, molded pulp dryer, customizable drying system, industrial infrared oven

Composition of Production Line:

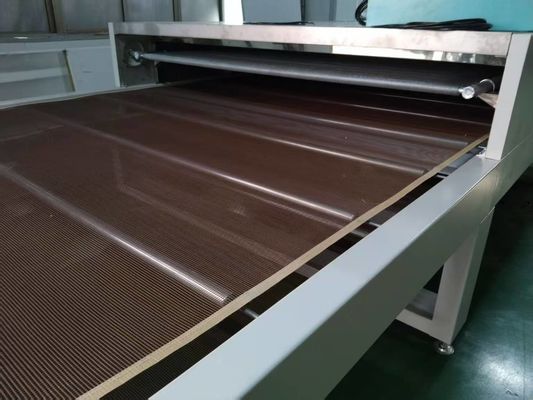

Pre-drying infrared module, main infrared drying tunnel, heat circulation system, temperature control cabinet, conveyor belt system, cooling section, PLC control panel

Product Description:

This infrared drying line is specifically designed for rapid and uniform drying of furniture boards (MDF, particleboard) and molded pulp products. It ensures moisture removal with minimal energy consumption and reduced footprint compared to conventional drying methods.

Technical Parameters:

| Parameter | Specification |

|---|---|

| Heating Technology | Medium-wave infrared emitters |

| Temperature Range | 50-400°C (customizable) |

| Belt Width | 600-2000mm (customizable) |

| Drying Speed | 0.5-5 m/min (adjustable) |

| Power Supply | 380V/50Hz/3Phase (configurable) |

| Control System | Siemens PLC + 10" HMI touchscreen |

| Heating Power | 30-200kW (customizable based on capacity) |

Application:

Drying of furniture boards, molded pulp packaging, egg trays, and industrial fiber products.

Customization:

Fully customizable infrared emitter layout, belt width, heating zones, and temperature profiles to match specific product requirements.

Feature:

-

40% energy saving compared to hot air drying

-

Uniform heating without surface overheating

-

Quick response and precise temperature control

-

Minimal maintenance requirements

Support and Services:

Installation supervision, operator training, 24/7 technical support, spare parts supply

Packing and Shipping:

Modular design for easy shipping, weather-proof packaging, FOB/CIF terms available

FAQ:

Q: Can the line handle different product thicknesses?

A: Yes, the temperature and speed are fully customizable for various thicknesses.